Difference Between Stepper Gear Motor and DC Motor

Sep 18, 2023|

Sep 18, 2023| View:262

View:262What Is Stepper Gear Motors

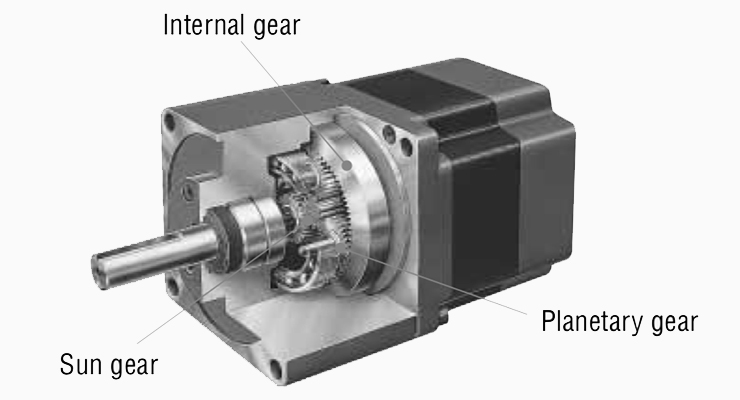

Stepping gear motors, also known as stepper motors with gearboxes, are a type of electromechanical device designed for precise motion control and positioning. These motors are characterized by their ability to move in discrete steps, with each step representing a fixed angle of rotation. Stepper gear motors often incorporate a gearbox to enhance torque output and reduce step size, enabling finer control.

What Is DC Motors

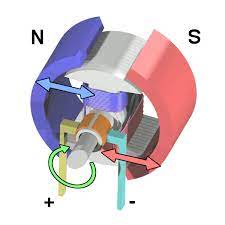

DC motors, on the other hand, are electrical machines that convert direct current (DC) electrical energy into mechanical motion. They operate on the principle of electromagnetic induction, using the interaction between magnetic fields to produce rotational motion. DC motors can be further categorized into brushed DC motors and brushless DC (BLDC) motors, each with its unique characteristics.

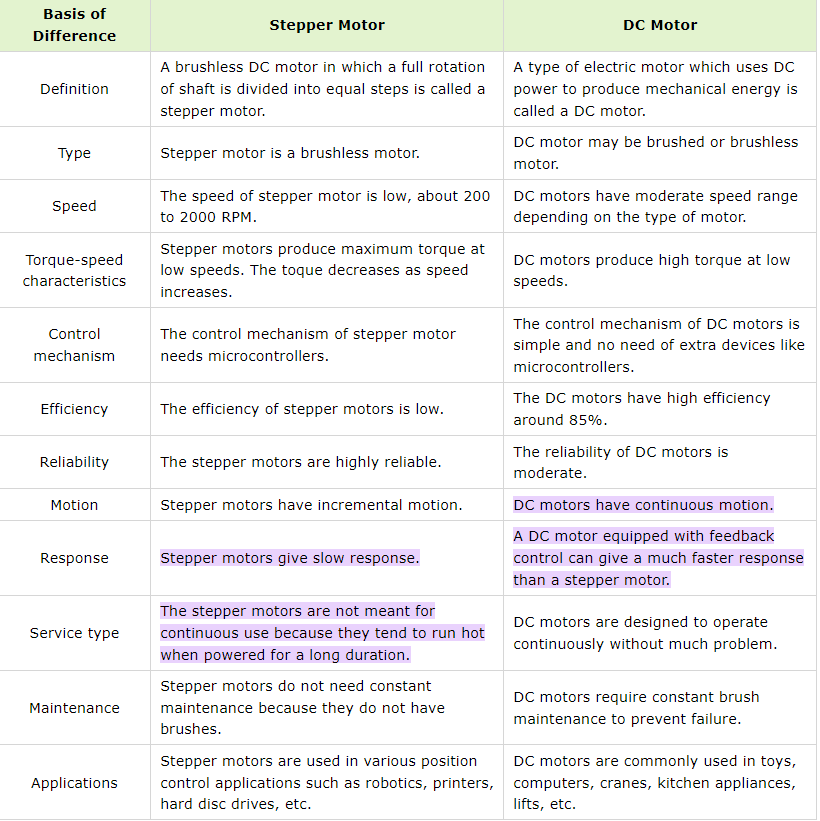

The primary distinction between stepper gear motors and DC motors lies in their working principles and the domains to which they are best suited.

Stepper gear motors operate by dividing a full rotation into a precise number of steps or increments. Each step corresponds to a fixed angle, typically 1.8 degrees for a full step in most configurations. This discrete movement allows for exceptional precision and control, making stepper gear motors ideal for applications where accurate positioning and motion control are paramount.

Stepper gear motors find their niche in a wide range of applications, including CNC machines, 3D printers, robotics, automated testing equipment, and positioning systems. They excel in scenarios where precise, repeatable movements and holding torque are essential. Additionally, they are often chosen for applications that require open-loop control, simplifying the control system.

DC motors, whether brushed or brushless, offer continuous rotation rather than discrete steps. They are prized for their simplicity, efficiency, and ability to generate high-speed, continuous motion. While they may not offer the same inherent precision as stepper gear motors, they excel in applications that demand high-speed rotation, continuous operation, and variable speed control.

DC motors are widely used in the automotive industry for powering electric vehicles and various vehicle components. They also find applications in fans, pumps, conveyor systems, and wherever continuous and variable-speed motion is required. The brushless DC motors, in particular, are favored for their efficiency and reliability in applications like drones, industrial automation, and HVAC systems.

Stepper gear motors are known for their reliability and low maintenance needs. They do not require brushes or commutators, which are common wear components in some types of DC motors. However, proper care should be taken to ensure that the mechanical components, such as the gearbox, remain lubricated and in good working condition. Routine inspections and occasional lubrication are typically sufficient to keep stepper gear motors running smoothly.

The maintenance of DC motors varies depending on whether they are brushed or brushless:

Brushed DC Motors: These motors require more frequent maintenance due to the wear and tear of brushes and commutators. Brushes may need replacement periodically, and commutators should be kept clean to prevent performance degradation.

Brushless DC (BLDC) Motors: BLDC motors are relatively low-maintenance compared to brushed DC motors. They lack brushes and commutators, reducing the need for regular servicing. However, routine inspections of the motor's bearings and electronic components may still be necessary.

As a trusted Stepping Gear Motor factory, we are committed to offering top-quality products tailored to your specific needs. Whether you require,High Efficiency Gear stepper Motor or DC motors, our extensive product range caters to a wide array of applications and industries.