Brushed dc Motor and Brushless dc Motor

Sep 15, 2023|

Sep 15, 2023| View:295

View:295Electric motors are ubiquitous in our modern world, powering everything from household appliances to industrial machinery. Two common types of electric motors are brushed DC motors and brushless DC motors. While both serve the same fundamental purpose of converting electrical energy into mechanical motion, they do so through different principles and come with distinct advantages and disadvantages.

Brushed DC Motors:

A brushed DC motor is the more traditional of the two, and its operation is relatively simple. It consists of two main parts: the stator and the rotor. The stator contains permanent magnets, while the rotor is the rotating part that carries the armature winding. Brushes, usually made of carbon, make physical contact with the commutator, a split ring attached to the rotor. When voltage is applied to the brushes, current flows through the armature winding, creating a magnetic field. This field interacts with the stator's magnetic field, causing the rotor to rotate.

Advantages of Brushed DC Motors:

Simplicity: Brushed DC motors are straightforward in design, making them cost-effective and easy to manufacture.

Control: They offer excellent speed control and are suitable for applications requiring precise speed adjustments.

Affordability: Brushed DC motors are generally less expensive upfront compared to their brushless counterparts.

Disadvantages of Brushed DC Motors:

Brush Wear: The brushes in brushed DC motors wear out over time and need regular replacement, leading to maintenance costs.

Limited Lifespan: Due to brush wear, the overall lifespan of brushed DC motors tends to be shorter.

Lower Efficiency: They are less energy-efficient compared to brushless DC motors due to friction and wear in the brush-commutator system.

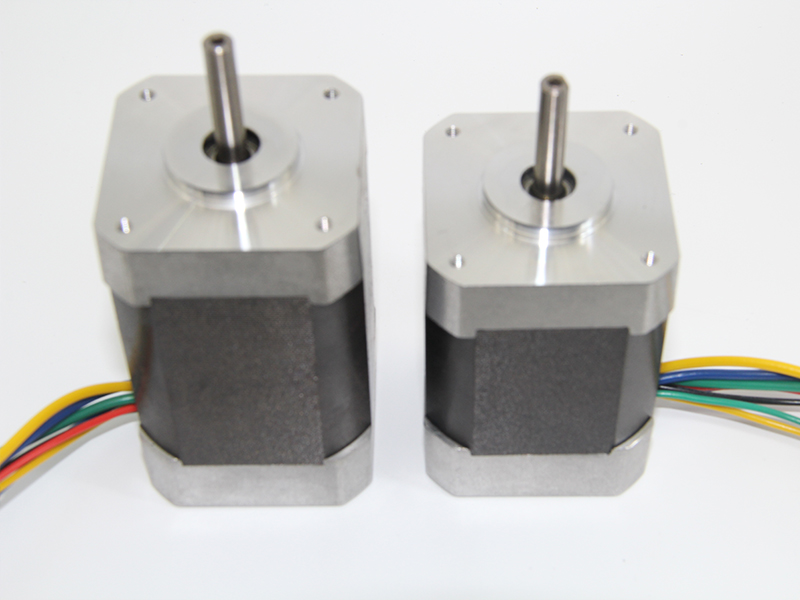

Brushless DC Motors:

Brushless DC motors, also known as BLDC motors, have gained popularity in recent years, especially in applications where efficiency, reliability, and long-term performance are critical. The core difference lies in the absence of brushes and commutators. Instead, BLDC motors employ a more advanced design that includes a stator with permanent magnets and a rotor with windings.

The operation of a brushless DC motor is governed by electronic controllers. When current is applied to the windings on the rotor, it generates a rotating magnetic field that interacts with the stator's fixed magnets, propelling the rotor into motion. The controller precisely manages the timing and intensity of the current to ensure smooth and efficient operation.

Advantages of Brushless DC Motors:

Higher Efficiency: BLDC motors are significantly more energy-efficient because they lack the friction and wear associated with brushes and commutators.

Extended Lifespan: With no brushes to wear out, brushless DC motors can have a much longer operational lifespan.

Reduced Maintenance: The absence of brushes eliminates the need for regular maintenance, reducing downtime and costs.

Better Performance: BLDC motors offer improved torque-to-weight ratios, higher power density, and faster response times.

Disadvantages of Brushless DC Motors:

Complexity: The electronic controllers and sensors required for BLDC motor operation can make them more complex and expensive to manufacture.

Control Complexity: Achieving precise speed control can be more challenging due to the need for advanced electronic systems.

Initial Cost: Brushless DC motors tend to have a higher initial cost, although their long-term benefits often outweigh this drawback.

In conclusion, both brushed DC motors and brushless DC motors have their own set of advantages and disadvantages. Brushed DC motors are simple and cost-effective but come with maintenance and efficiency drawbacks. In contrast, brushless DC motors offer higher efficiency, longer lifespan, and reduced maintenance requirements, making them a preferred choice for applications where reliability and performance are paramount.the most important things is choose a realible brushless dc motor factory