Stepper Motors Demystified

Feb 01, 2024|

Feb 01, 2024| View:84

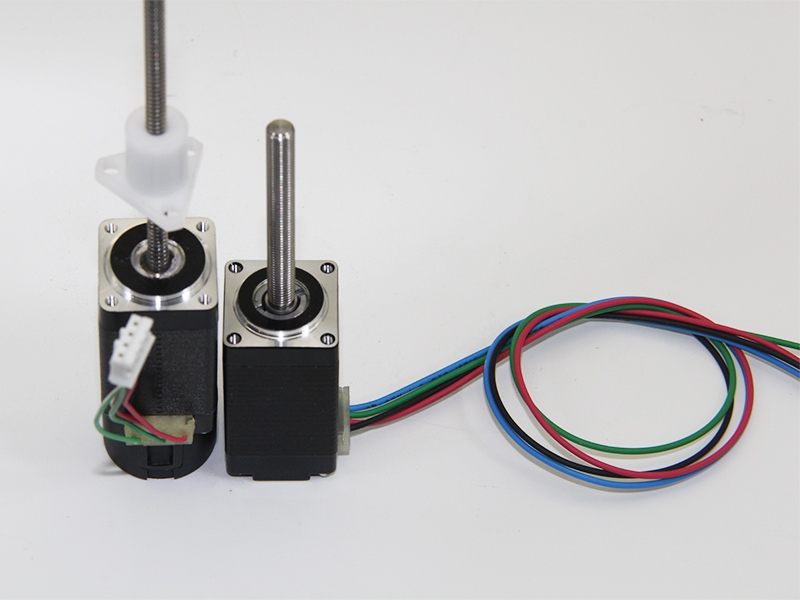

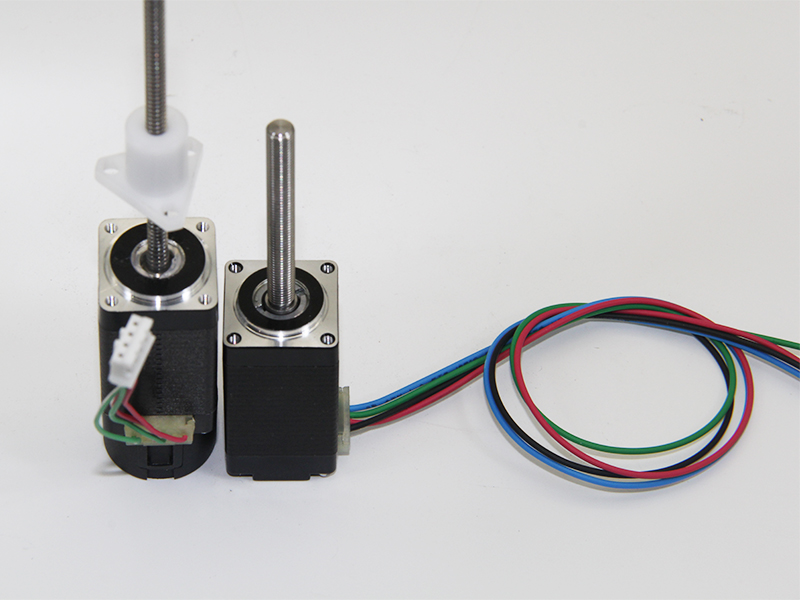

View:84Stepper motors have become the cornerstone of precision control systems in a wide range of industries. As a leading supplier specializing in the production, research, and sales of brushless motors and stepper motors in China, Changzhou Sino-Pan Electrical Co.,Ltd. is at the forefront of providing innovative solutions.

Stepper motors are electromechanical devices designed to convert electrical pulses into precise mechanical motion. They are widely utilized in applications that demand accurate positioning and controlled movement. Unlike traditional motors, stepper motors move in discrete steps, making them ideal for applications requiring precise control over position and angle. This unique characteristic allows for high accuracy and repeatability in motion control systems. Stepper motors come in various types, including permanent magnet, variable reluctance, and hybrid stepper motors, each with its own advantages and applications.

Stepper motors operate based on the principle of electromagnetism. They consist of a rotor and a stator. The rotor is typically composed of a permanent magnet or toothed ferromagnetic material, while the stator comprises multiple electromagnetic coils. By energizing the coils in a specific sequence, magnetic fields are generated, which either attract or repel the rotor's poles. This interaction causes the rotor to move in precise increments, known as steps. The sequence and timing of the coil energization determine the direction and speed of the motor's rotation. Modern advancements in stepper motor technology have led to the development of closed-loop stepper systems, incorporating feedback mechanisms to enhance accuracy and performance.

Stepper motors operate by applying current to their windings, generating magnetic fields that induce rotational motion. There are two common types of stepper motors: permanent magnet and hybrid. Permanent magnet stepper motors utilize permanent magnets to generate the magnetic field, while hybrid stepper motors combine the characteristics of permanent magnets and electromagnetic coils.

Permanent Magnet Stepper Motors

Permanent magnet stepper motors utilize permanent magnets to generate the magnetic field required for rotation. The rotor consists of a multi-pole permanent magnet, while the stator contains multiple electromagnetic coils. When current flows through the coils, magnetic fields are produced, attracting the rotor's permanent magnet poles. By alternating the current flow through the coils in a specific sequence, the rotor steps in precise increments, enabling controlled positioning and rotation. Permanent magnet stepper motors are known for their simplicity, cost-effectiveness, and high torque output.

Hybrid Stepper Motors

Hybrid stepper motors combine the characteristics of permanent magnet and variable reluctance stepper motors, resulting in improved performance and versatility. The rotor in a hybrid stepper motor consists of both permanent magnets and toothed ferromagnetic material. The stator also contains multiple electromagnetic coils. By energizing the coils in a specific sequence, the magnetic fields interact with the rotor's permanent magnets and teeth, causing the rotor to step forward. Hybrid stepper motors offer several advantages, including higher resolution, smoother operation, and increased torque compared to permanent magnet stepper motors.

When comparing stepper motors with other motor types, such as DC motors, AC motors, and servo motors, it is essential to consider their unique advantages and limitations. Unlike DC motors, stepper motors do not require complex feedback systems to achieve precise positioning. They offer high holding torque at low speeds, making them suitable for applications requiring accurate positioning and high torque. Stepper motors are cost-effective compared to servo motors, which require additional feedback devices. While AC motors excel in continuous rotation and high-speed applications, stepper motors provide precise control over position and angle, making them indispensable in automation, robotics, and various other industries. Recent advancements in motor control technology, such as closed-loop stepper systems and integrated motor drives, have bridged the gap between stepper motors and servo motors, offering improved performance and accuracy.

Comparison with Other Motor Types

When comparing stepper motors with other motor types, such as DC motors, AC motors, and servo motors, it is essential to consider their unique advantages and limitations. Unlike DC motors, stepper motors do not require complex feedback systems to achieve precise positioning. They offer high holding torque at low speeds, making them suitable for applications requiring accurate positioning and high torque. Stepper motors are cost-effective compared to servo motors, which require additional feedback devices. While AC motors excel in continuous rotation and high-speed applications, stepper motors provide precise control over position and angle, making them indispensable in automation, robotics, and various other industries. Recent advancements in motor control technology, such as closed-loop stepper systems and integrated motor drives, have bridged the gap between stepper motors and servo motors, offering improved performance and accuracy.

Stepper motors find extensive use in various fields, contributing to the efficiency and accuracy of numerous automated systems and equipment. They are widely employed in printers, CNC machines, 3D printers, robotics, textile machinery, medical devices, vending machines, and many more. The exceptional positioning capabilities and controllability of stepper motors make them an ideal choice for applications requiring precise positioning and angular control.

Stepper motors have revolutionized the world of precision control with their unique characteristics and versatile applications. As a leading supplier in the industry, Changzhou Sino-Pan Electrical Co.,Ltd. remains dedicated to pushing the boundaries of stepper motor technology through continuous research and development. With their exceptional performance and reliability, stepper motors will continue to drive advancements in automation, robotics, and various other industries, enabling precise and efficient control over motion.