Advantages and Disadvantages of Stepping Motors

Sep 07, 2023|

Sep 07, 2023| View:281

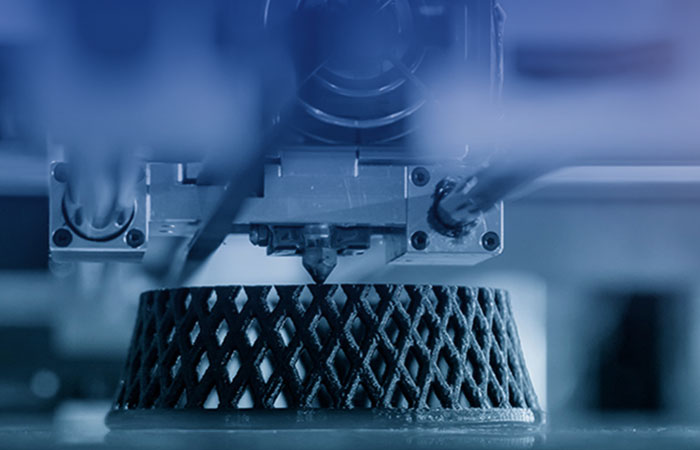

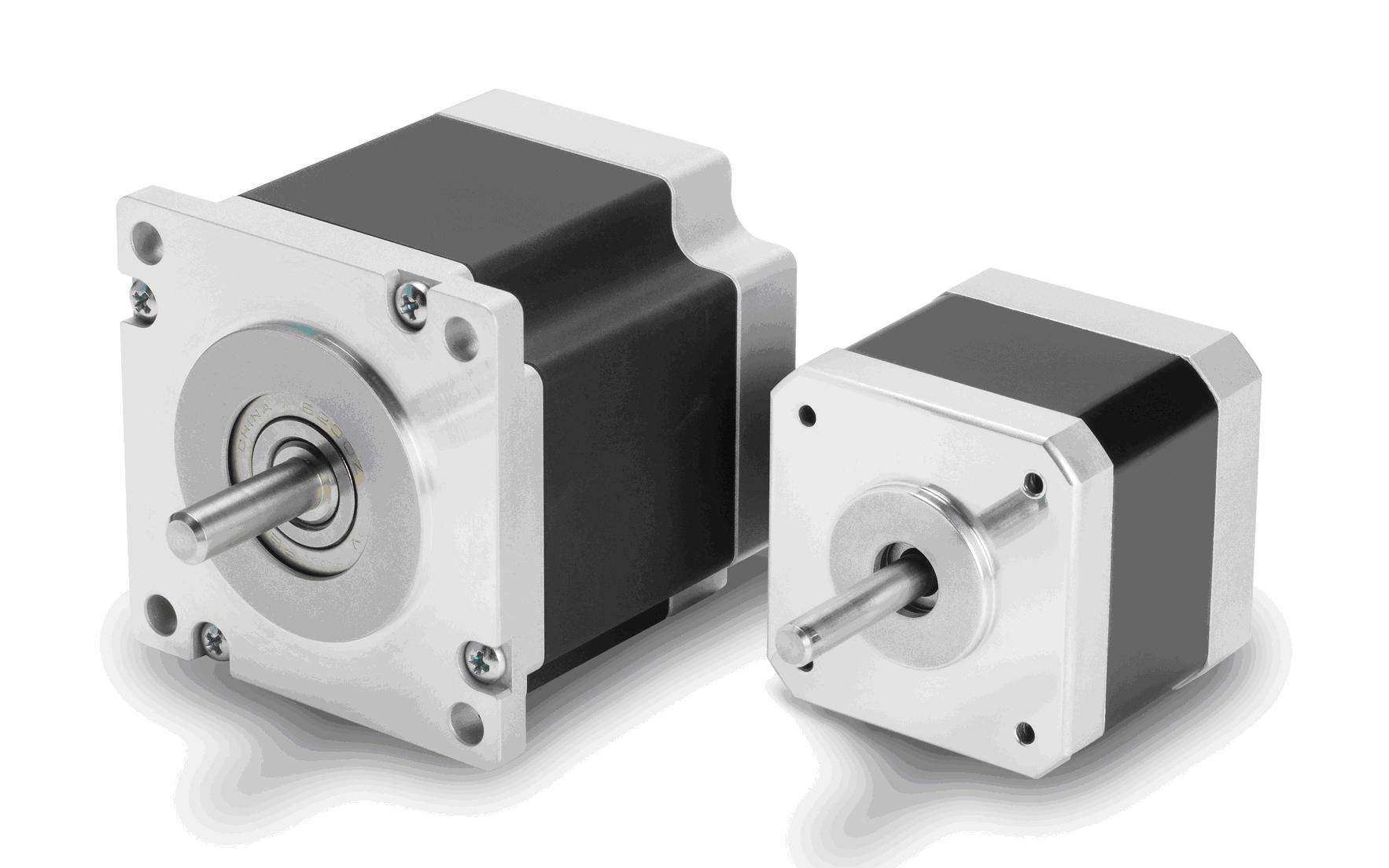

View:281Stepping motors, also known as step motors or stepper motors, are widely used in various industries and applications for their precise control and simplicity. These electromechanical devices convert electrical pulses into discrete mechanical movements, making them an essential component in robotics, CNC machines, 3D printers, and more. While stepping motors offer several advantages, they also come with their fair share of disadvantages. In this article, we will explore both sides of the coin to better understand the capabilities and limitations of stepping motors.

Advantages of Stepping Motors

Precise Positioning

One of the primary advantages of stepping motors is their ability to provide highly accurate and repeatable positioning. Unlike other types of motors, stepping motors move in discrete steps, which allows for precise control over the rotation angle and position. This precision is essential in applications where accuracy is critical, such as in CNC machines, 3D printers, and telescopes.

Open-Loop Control

Stepping motors can operate in open-loop control systems, meaning they don't require feedback devices like encoders for position sensing. This simplifies the control system and reduces costs. Open-loop operation is possible because the motor moves a fixed number of steps for each input pulse, making it inherently predictable. This is particularly advantageous in applications where the cost and complexity of closed-loop control systems are prohibitive.

High Torque at Low Speeds

Stepping motors provide substantial torque at low speeds, which makes them ideal for applications requiring precise control of slow-moving or stationary loads. This high torque capability at low speeds allows them to hold a position without overheating or requiring additional gearing mechanisms, which can be the case with other types of motors.

Reliability

Stepping motors are known for their reliability and robustness. They have a simple construction with fewer parts prone to wear and tear compared to other motor types. This simplicity contributes to their long service life, making them suitable for continuous operation in various industrial environments.

Cost-Effective

Stepping motors are relatively affordable compared to some other motor types, especially when considering their precision and reliability. The simplicity of their control system also contributes to cost savings. This cost-effectiveness makes them a popular choice in applications where tight budgets are a concern.

High Holding Torque

Stepping motors can maintain a stable position without any power input, thanks to their holding torque. This feature is beneficial in applications where the motor needs to resist external forces or hold a load in place, such as in camera gimbal systems or medical devices.

Disadvantages of Stepping Motors

Limited Speed Range

One of the most significant disadvantages of stepping motors is their limited speed range. They excel at low-speed applications but struggle to maintain high speeds efficiently. As the speed increases, the torque output diminishes rapidly, leading to a phenomenon known as "cogging." This limitation restricts their use in applications requiring high-speed continuous rotation.

Lack of Smooth Motion

Stepping motors produce motion in discrete steps, which can result in a noticeable "stepping" effect in certain applications, especially when moving at slow speeds. This characteristic can lead to vibrations and noise, making them unsuitable for applications that demand smooth and quiet motion, like high-end camera gimbals.

Resonance Issues

Stepping motors are susceptible to resonance, a phenomenon where mechanical vibrations can cause a loss of accuracy and even lead to missed steps. Controlling resonance can be challenging and often requires additional damping mechanisms or sophisticated control algorithms.

Heat Generation

Stepping motors can generate significant heat during operation, particularly when they are stationary or holding a load. This heat can affect the motor's performance and may require additional cooling measures or derating of the motor's specifications.

Complex Control at High Speeds

While stepping motors are known for their simplicity in open-loop control, achieving accurate control at high speeds can be challenging. At high speeds, the motor's response time becomes a critical factor, and maintaining accuracy may necessitate complex control algorithms and additional feedback mechanisms.

Power Inefficiency

Stepping motors tend to be less power-efficient than some other motor types, especially when operating at low speeds or holding a position for extended periods. In applications where power consumption is a significant concern, such as battery-powered devices, alternative motor types like brushless DC motors may be more suitable.

Stepping motors offer several advantages, such as precise positioning, open-loop control, high torque at low speeds, reliability, and cost-effectiveness. These characteristics make them well-suited for a wide range of applications, particularly those requiring accurate and repeatable positioning.

However, stepping motors also have their fair share of disadvantages, including limited speed range, lack of smooth motion, susceptibility to resonance, heat generation, complex control at high speeds, and power inefficiency. These limitations can restrict their suitability in certain applications, particularly those demanding high-speed continuous rotation and smooth, quiet motion.

when it comes to selecting the right motor for your application, it's crucial to carefully assess your specific needs and take into account the advantages and disadvantages of stepping motors discussed above. The choice of motor can significantly impact the performance and efficiency of your project. As a reliable stepper motor supplier, we understand the intricacies of stepper motor technology and can provide you with expert guidance to help you make an informed decision. Don't hesitate to reach out us for assistance in finding the perfect stepper motor solution tailored to your needs.